en

it

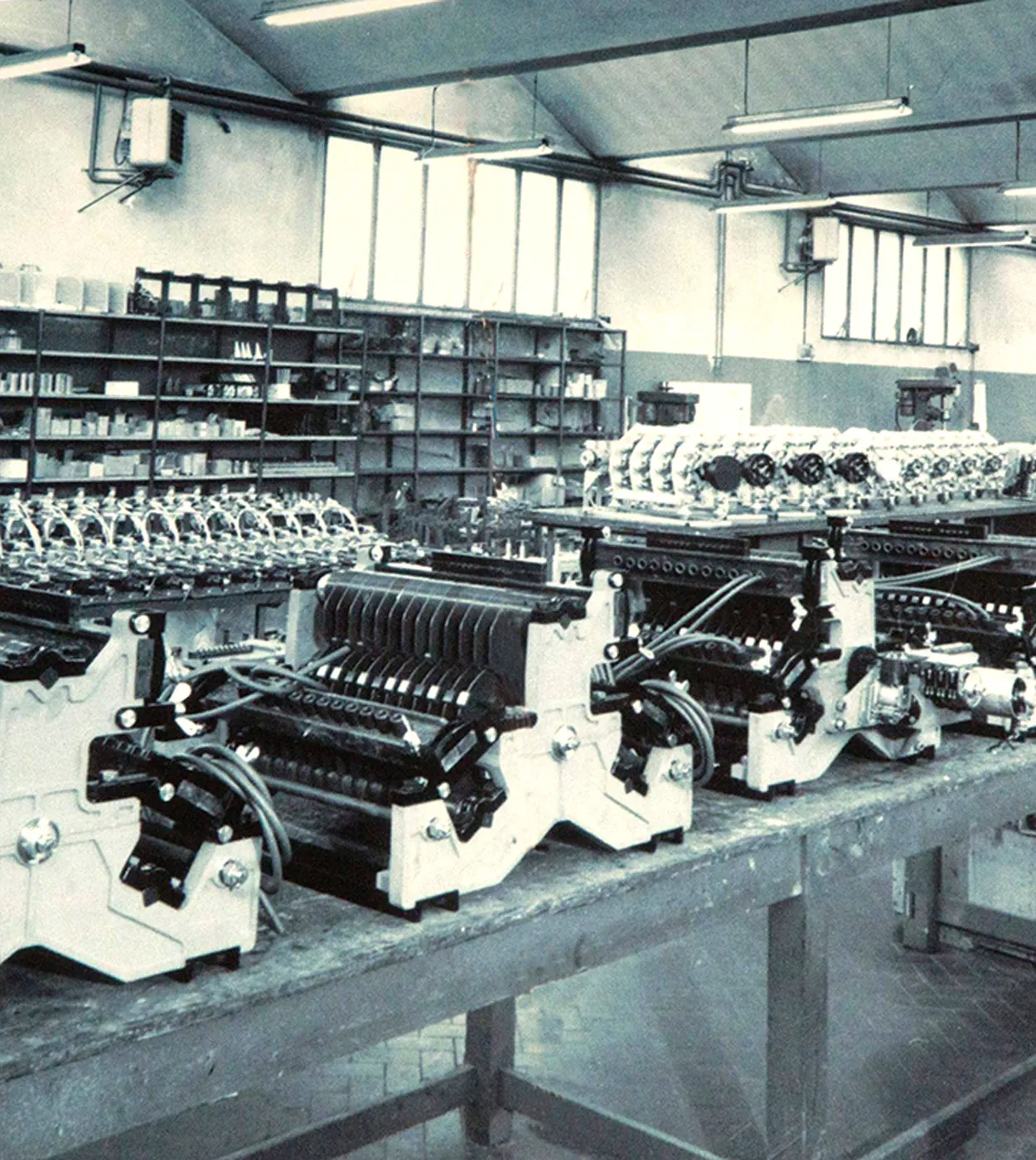

FIRST PRODUCTION OF SLEEPERS

This year it marked the birth of Niccoli e Naldoni, a well-known Italian railway company dedicated to producing railway signalling components and equipment, which is acquired by WEGH group in 1996.

At the Gorlago (BG) plant of I.P.A. (Industria Prefabbricati e Affini), the first production of FS35 and later FSV35 sleepers began, with a production capacity of approximately 600 sleepers/day.

BIMA and OLMI, now WEGH Group, produce the first Long Line and Carousel production plants, for the production of prestressed reinforced concrete sleepers.

At the Calcinate (BG) plant of I.P.A. (Industria Prefabbricati e Affini), the first production of turnout bearers for railway equipment began with an amount of approximately 100 pieces/day produced.

IPA Ferroviaria, an important Bergamo-based company for the production and design of prestressed reinforced concrete products.

In 1987, it was the first in Europe to produce ballast-less track systems with prefabricated slabs.

S.I.C.I. IMPIANTI, now WEGH Group, acquires BIMA, a company with significant know-how in precast concrete and concrete railway sleepers’ production plants.

1996 was the year of the acquisition of L.E.S. Elettronica, to implement electronic expertise in the railway sector within the Group.

In 2009, the WEGH Group achieved a goal of global significance. The world’s largest plant for the production of concrete railway sleepers is built in Brazil.

WEGH acquires IPA International and IPA Ferroviaria intending to become one of the only companies in the world with dual Process and Product know-how.

The first joint venture is established in Mozambique by WEGH Group.

Thanks to the installation of our concrete elements production plant, which is managed almost exclusively by local staff, it quickly achieves production averages exceeding 7% of nominal capacity

WEGH Group acquires another pioneering company, OLMI, with its important expertise and references in producing plants for prestressed concrete sleepers and turnout bearers by Carousel system. From there a new production plant has been developed in Calcinate, with a production capacity of 180 sleepers/hour.

WEGH expands its Signalling Business Unit production sites with a new factory in the province of Prato, to increase electro-mechanical equipment production.